Don’t you love it when hard work starts to pay off, dear readers? Months and months of steady slog and what appears to be fiddling about – even to those who are doing the work – and then Kerpow! Suddenly everything comes together in a few hours and everyone walks about smiling for days afterwards. After a very busy last few weeks, I’m still smiling. It feels like we are making real headway, and we are able to show you some of the results of our efforts. (Of course we’ve had some really cracking cooked breakfasts and a lot of tea, too.) So where do we start?

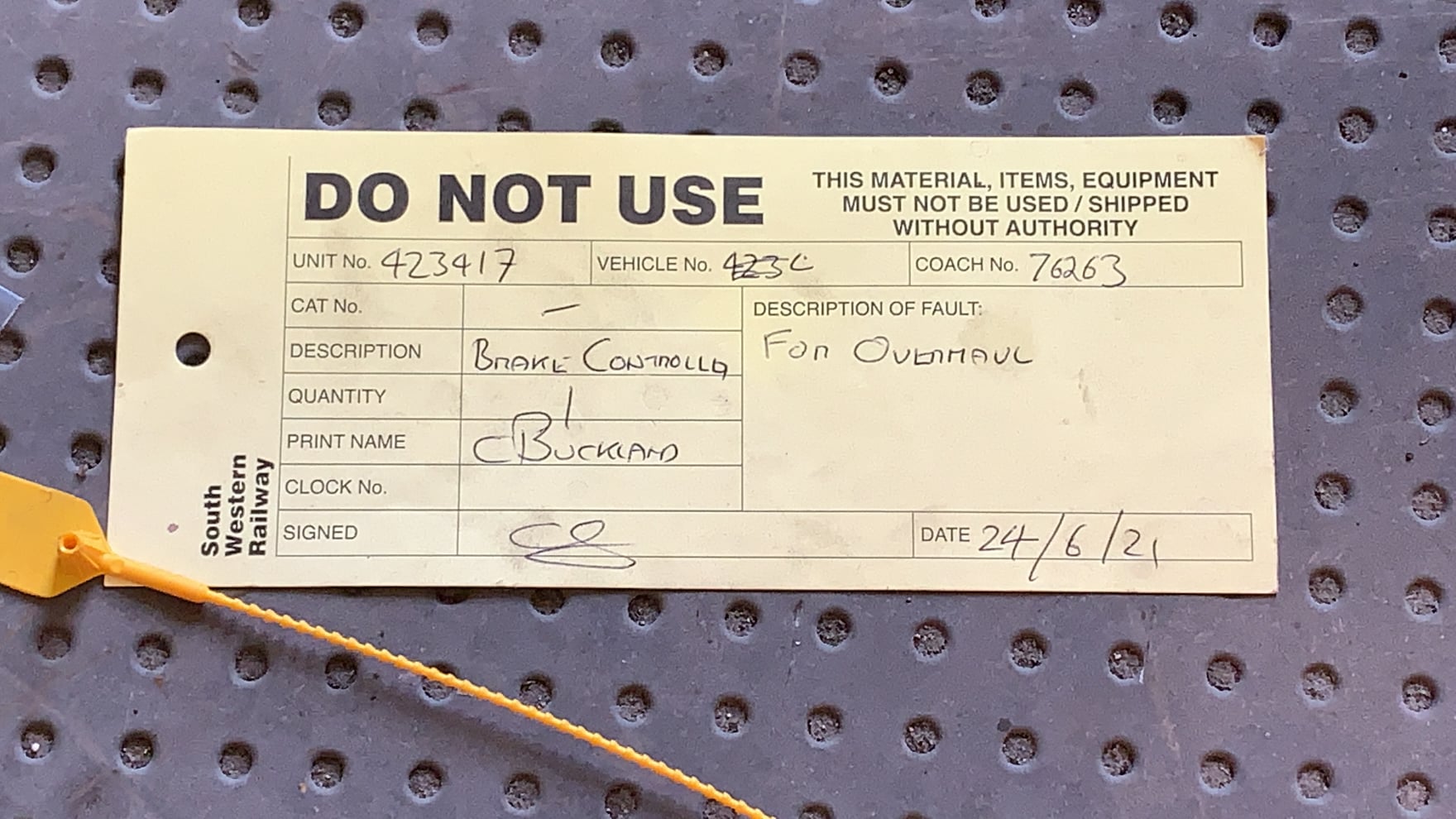

The brake chests and controllers are back from Railway Brake Services, along with some additional sundries that it was decided should be overhauled in addition to the initial batch of parts. While our friends at Armstrong Powerhouse underwrote the overhaul of the brake controllers and brake chests, the SETG took the decision to underwrite the overhaul of the additional sundries; these included relays, valves and manifolds. As I type this, we are preparing to re-fit the overhauled bits and pieces and begin testing on the equipment ‘in situ’. It’ll be good to see the unit standing in the shed without the “Brakes Isolated” tags hanging from it! In addition to the brakes themselves we have received the batch of re-calibrated brake gauges which were sent away for overhaul a few months ago. All bar one of the original gauges were able to be reused, and we have a spare for the one that failed – lesson: always keep spares! Once the brake chests, controllers and gauges are refitted we will once again be able to ‘pump up’ the brakes; once testing is complete, there will only be a few details to attend to before the unit can leave the shed.

Work on the cab of 76263 (the ‘Rough One”) is continuing, with the fresh panelling having been test-fitted. The inner-face of the bodywork has been treated to protect the metal against any further water ingress (steel and water don’t mix) and the next job is to fit new insulating material. As with the rest of the unit the old fibreglass insulation has been stripped out and replaced with Rockwool because of a) age, b) it has a nasty habit of retaining water, c) it’s very good at reducing noise and d) the bloody moths don’t like it. Once that has been put in we will do a final fit of the cab panels, fill and undercoat as required before a few coats of Opaline Green are applied. As with the cab on 76262, we have removed the driver’s seat so that the frame can be cleaned and repainted. While I’m thinking about it, we’ll also make time to remove and repair the second man’s seat on 76263; a particularly heavy railway employee must have sat on it at some point (probably an instructor, a manager or a travelling fitter*) and some fettling is required! With the fitting of the overhauled brake controller, new seats, fresh panelling and a coat of paint, this will be as goos as the cab has looked in more than a decade.

* – Shots fired! Potter wrote it!!

The Trim Shop has now finished overhauling the standard class seat bases. This is the culmination of a job that has taken more than two years and counts as the single largest piece of the overall restoration. Without the efforts of Maggie and Lynn Abrahams, ably supported by Doug Abrahams and Paul Cooper, we would have put this job out to tender, and we estimate their work has saved the group more than £10,000. What price volunteers, eh?! With the standard class seat re-trimmed and awaiting refitting, the Minions made a spur-of-the-moment decision last week to partial refit of the seat bases and backs to 76263 and the results speak for themselves; what was a wreck a few years ago is almost fit for traffic. Darren has done a stunning job making up and fitting the new interior window trims as well as working to fit new window drains so that we can avoid a repetition of the water damage the unit suffered during open storage, Trousers and Lynn made the repair to the floor (Lynn said she’d had enough of bloody seats for a bit), Buckie and Darren have worked on the cab and Potter has made the tea.

Team work does, indeed, make the dream work.

At present, the non-driving side of the standard saloon requires work on the 3-wide seat frames, but the driver’s side of the coach is complete. The satisfaction of seeing people sitting on those seats again was immense. The satisfaction when we have ticket-holding passengers are sat on them instead will be ten-fold greater! The first class compartments on 76263 are due a heavy clean and the replacement of several seat bases (the next job for the Trim Shop – more sewing and more learning on the job), as well the stripping out and replacement of some heavily water-damaged internal panelling and quarter pads. This at least is work we have carried out previously on 76262, so (famous last words) should go relatively smoothly.

The next major job for the exterior will be fitted the stepboards. At the moment Richard Salmon of the Bluebell Railway, who has already put in an invaluable contribution to the project by machining and cutting the blank timber paid for by Tom Cairns of RealTime Trains, is now occupied with test-fitting each step board to its allocated position on the train. There are more than 30 boards of varying lengths and Richard, being far more organised than your standard Minion, has a spreadsheet and numbering system so that he know where every board will go. Potter, who can sometimes be stumped by shoelaces and door handles, watches this kind of precision in awe. Once the test fitting for each coach is complete the boards will be stored until the frames have been needle-gunned to remove any rust and then painted. Once this is done, the boards themselves will be painted and bolted in place. Having seen how good the unit looks with the unpainted boards in place (it makes it look ‘complete’ for the first time in years), we’re very excited to see them finally in place and bolted in properly.

While all this is going, behind the scenes we are carrying on with our efforts to bring the SETG fully up to Big Railway standards. Buckie has been updating and adding to the work systems already in place to ensure that we stay on top of the paperwork and adhere as far as possible to the latest industry requirements. This will be an ongoing project – much to Buckie’s frustration who is often heard to grumble that he seems to spend more time doing paperwork than working on 3417. The shop continues to be active (have you bought your SETG mug yet?!) and we have an active presence on Facebook and Twitter; more than 3,000 followers on Facebook and another 3,000 on Twitter – which isn’t a bad effort for the least glamorous piece of rolling stock that BR ever built! Things are looking good for 3417, and we have ambitions to finally release the unit back into the public gaze soon. We will be back onsite tomorrow for the first workday in March, and will update you all accordingly. In the meantime, thank you for reading and don’t forget to support your friendly neighbourhood 4VEP!