Good afternoon everyone.

Important Non-Train Related Announcement: Espresso Martinis are a bad idea and you shouldn’t drink them because if you have too many they make your head want to fall off the next day. As I have found myself saying on many many previous occasions, “Never again.” Thank heavens for two days off. (Mind you, it was a very good birthday party!)

Now, on to matters of a slam door train preservation nature. There are three work days to report – two of them were routine, attended by two SETG Minions.

The third and latest workday was well attended and far from routine.

“Now, read on….”

Work Days 26th June/11th July 2020:

These two days were focussed on finishing details on 76262 which have been previously missed or were deemed lower priority jobs.

The two sessions involved removing the driver’s seat from the driving cab, dismantling it, stripping the old paint and applying a fresh coat of gloss black to the frame before refitting. The drivers sun visor, long removed to allow cab painting, was also repainted – although not before decades of opaline green was removed from the brass fittings. The result is something rather special – a well built 50-year old component that now looks brand new. The drivers fly doors were painted and had their metal fittings reattached. Again, with a little care and attention these metal fittings make the door look far, far better than was previously the case. Finally the cab itself was given a final top coat of Opaline Green paint. You can see from the pictures below that the hard work was, as usual, carried out to a high standard and the results are very impressive!

Work Day 23rd July 2020:

This day was very successful for a number of reasons but primarily because we were delighted to welcome South Western Railway’s Managing Director Mark Hopwood to the depot to inspect our progress. Our Chief Engineer Chris Buckland escorted Mark around the site, explaining the group’s origins and aspirations for the unit as well as giving him an overview of what has been achieved thus far. Part of his visit involved Mark filming a company update, broadcast via LinkedIn, which featured 3417 as a backdrop – thankfully the paintwork was clean!! Mark’s interest in the restoration project and our future aims was hugely gratifying and we look forward to welcoming him to the depot again in the future.

Away from the VIP visit, work continued at a surprising and very pleasing pace. Margaret and Lynn were back in the Trim Shop, and were attempting a ‘dual’ re-covering of a water damaged seat base. This involves not just replacing the wasted and damaged top moquette, but also the calico base cover which lies underneath it. This was the first time we’ve attempted a repair of this kind, so we were curious to see if it would be possible to do it ‘in-house.” As it turns out, it was not only possible but thanks to Margaret & Lynn’s skill and teamwork, it was a great success.

One very battered and dog-eared seat base.

Stripped of the old calico, and measured for a new cover.

The new cover, sewn, fitted and stapled to the original base.

Test fitted into a 2-seat bay in 70797. As good as new and just needing a top cover.

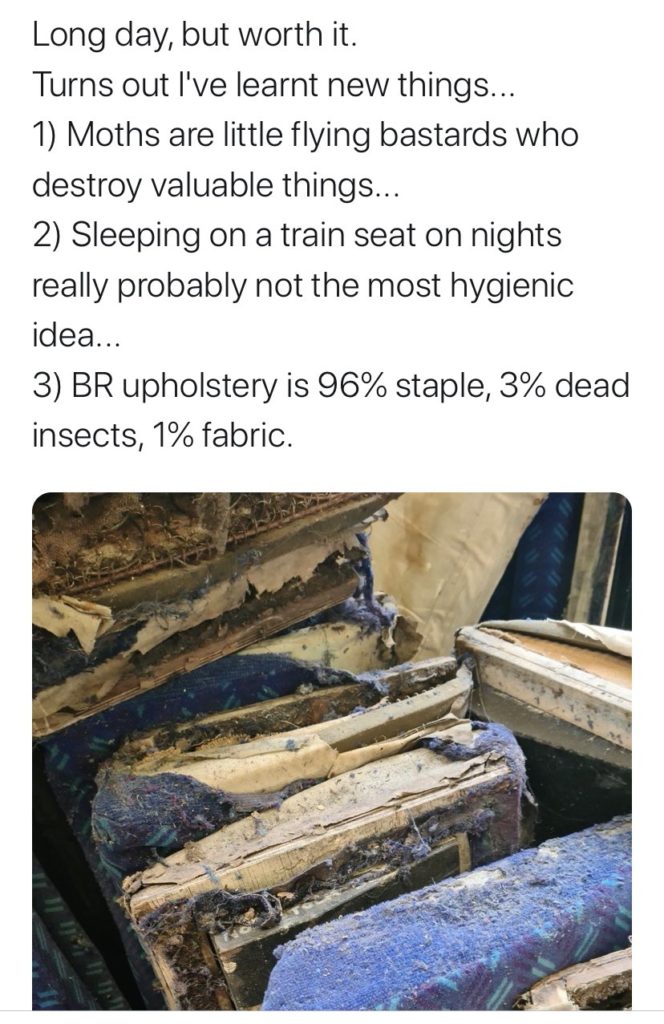

While Margaret and Lynn worked on the first seat base a small team spent a few gruelling hours removing wasted top moquette from some of the stack of remaining seat bases originally removed from the unit around 18 months ago. These bases have now dried out and the resident insect life has expired! However dust masks and gloves were essential – it’s amazing how much muck comes away from these bits of fabric as it is removed. It’s also surprising just how spiteful old staples can be when they’re being removed from bits of wood! The SETG’s Design Guru Paul Cooper summed things up very succinctly in this tweet he sent on Thursday night:

We have vacuum cleaned all the stripped seat bases and they are now ready to have new calico and top covers fitted. After this we will ‘bug bomb” them to ensure that any remaining pests are eliminated before we make them ready for installing back into the unit. While the retrimming is happening, we will be repairing water-damaged wooden fittings in motor coach 62236. The wooden batons to which the quarter pads are secured have rotted, and the bolts which secure the batons to the coach frame have in some cases rusted or sheared off. We will be removing the old bolts where possible, and cutting off & welding in fresh bolts where removal isn’t possible. After this, new quarter pads can be fitted, fresh seats bases and backs fitted and then bingo! Another serviceable coach! (Sounds easy, doesn’t it?!)

Away from the depot, we have begun a conversation with contractors on costs relating to the brake overhaul which the unit will need before it can once again be moved on Network Rail infrastructure. The components to be overhauled are the EP brake chests on each coach, as well as the driver’s brake controller in each cab. We had hoped to receive this estimate at the end of last week, but of course COVID-19 continues to disrupt working patterns. Once we have a details breakdown of costs, we will begin looking at ways to fund the work.

And that is it. A productive and busy few days, and a very encouraging response from SWR top brass regarding our presence and work here at Strawberry Hill. That’s all for the time being. We will leave you with this video of a very happy motorman testing the drivers seat on 76262.

The Minions will be taking a short break while they try to work out how to move 10 tons of vintage railway heritage from one room to another. More on this later!