Once upon a time there was a Minion. And this Minion was supposed to write updates for the SETG website, but his writing mojo deserted him and he grew distracted and disillusioned with the whole process. But lo! There came unto him a guiding light named Chris Buckland, who struck him about the head with a shoe paddle and spaketh with a Great Voice. “Good game, good game, cuddly toy, cuddly toy! Stop sodding about, Potter. Get on with updating the website, you great sack of jobbies in a belt”, said he. And thus was Potter galvanised to his task. “I must write Things”, he said whilst rubbing Savlon into the larger head lumps, “and I must inform the impatient readership (both of them) for there is news to impart.”

Now, read on…

As you will have read above, it’s been a while since the Writing Minion sat behind his desk and got a proper web update underway. The depot has been extremely busy, both with the immediate work of getting 3417 ready for its return to traffic and increasingly with one eye towards the next phase of the project; operations. The final stage of the re-wire of 70797 is now underway, and once that is completed we have the interior fittings prepared and ready to install once the wiring is complete and the heating system has been tested and signed off. JD and Mick are doing an excellent job, even more so when you consider that the work they are doing would have been given to a gang of at least 10 paid fitters at Eastleigh. What would be a fortnight’s worth of work in a large depot has stretched to months for us. But it will be done to the highest possible standard by volunteers who won’t settle for second best. (Lucky us.)

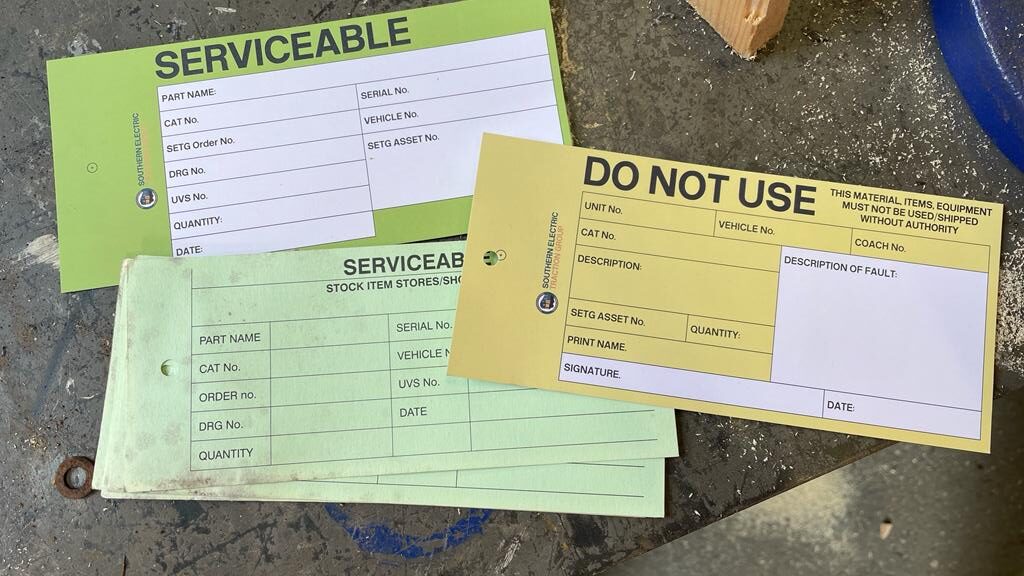

In the interests of moving the overall restoration forwards faster, and to help build closer ties with our chums at the Bluebell Railway, Roy Watts (bow-nod-tug-forelock) and Richard Salmon are in the first stages of assembling small working parties from the Bluebell Railway to visit us at Strawberry Hill. We’re hoping that, assuming they don’t run away screaming, we can expand the volunteer workforce and utilise some of the undoubted skills of the Bluebell volunteers to accelerate the restoration – COVID 19 stuffed our timetable (and everyone else’s) and we would like to try to correct that delay. On the subject of volunteers, Buckie (he of the Great Voice and Senior Spanner Fiddler) has been trawling Low Places and Pits of Vice for former colleagues who may be interested in spending some of their retirement working on a 4VEP. The good news is that, against all common sense, expectation and despite them having actually met Buckie, several of them have agreed. From this we already have a newly standardised paperwork system (glamorous, eh?), COSHH organised and filed, document control in place and being used, competency regime re-organised and in place, Planned General Inspection cycle agreed and implemented and old documents archived against future inspections. All of this dull but essential work is based on current industry best practice.

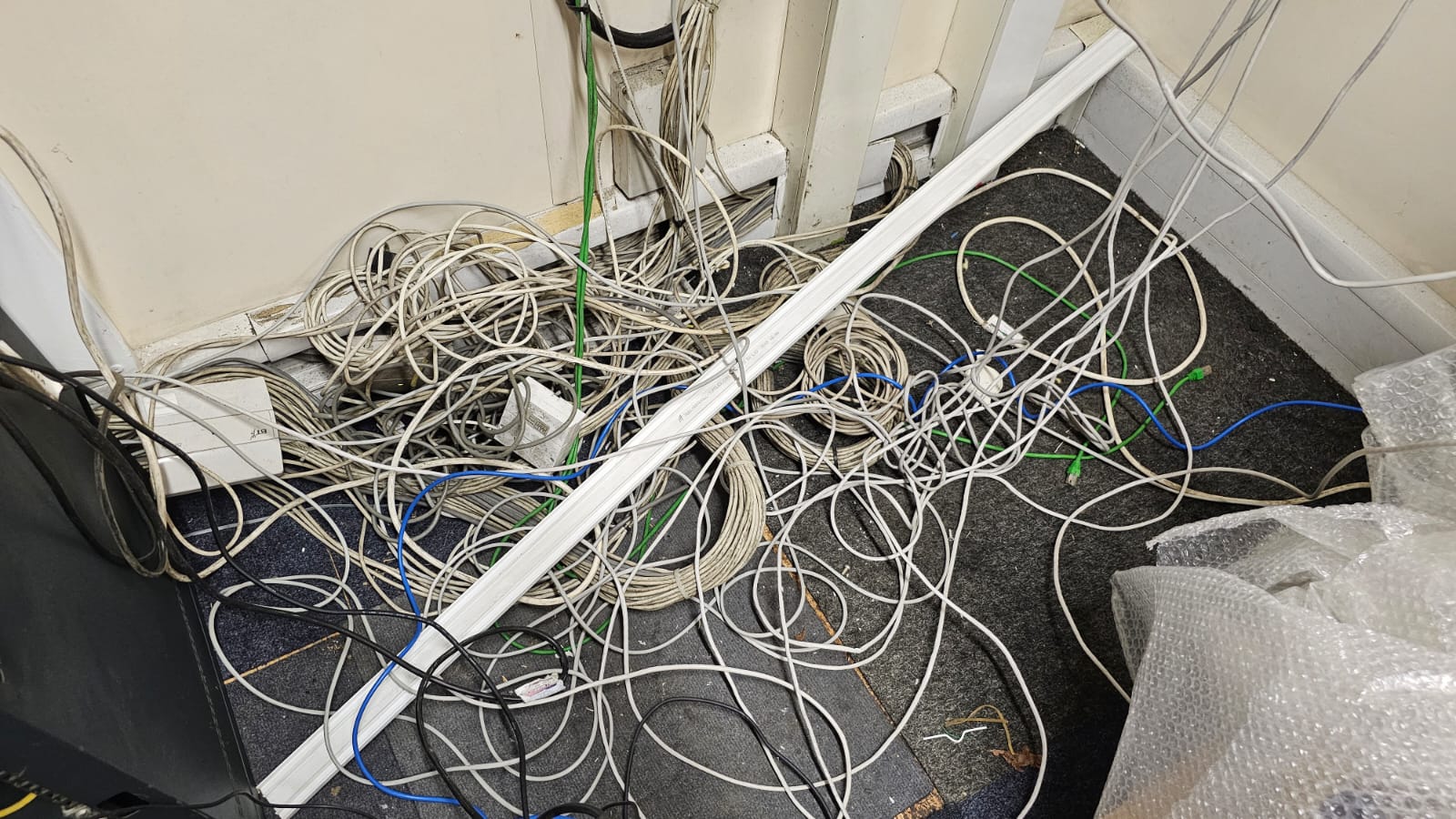

More Back Office upgrades have happened thanks to the Digital Minion; the old desktop has been comprehensively fettled, as well as the procurement of a second-hand laptop (which carries OTMR software installed – another nod to the future) and we have revived and are now using the IT server equipment that came with the portacabin. As we move towards digitising our stores inventory (more on that later) this will mean that we have IT equipment live both in the offices and the shed. Not bad for a small mob of enthusiasts and staff, eh?!

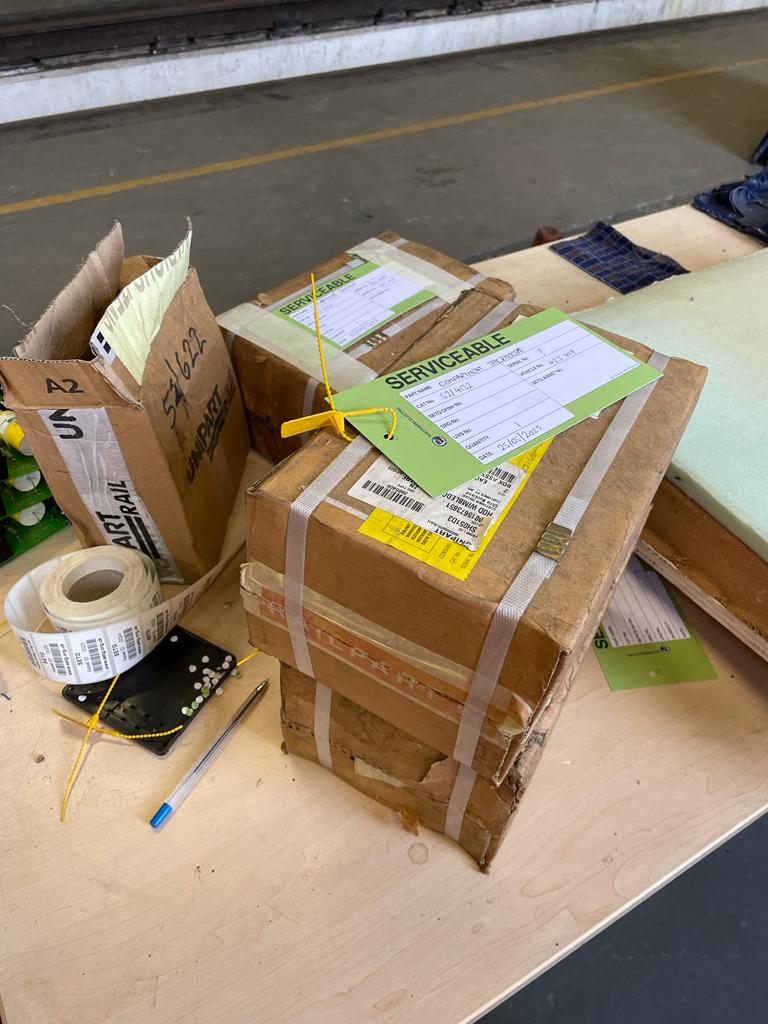

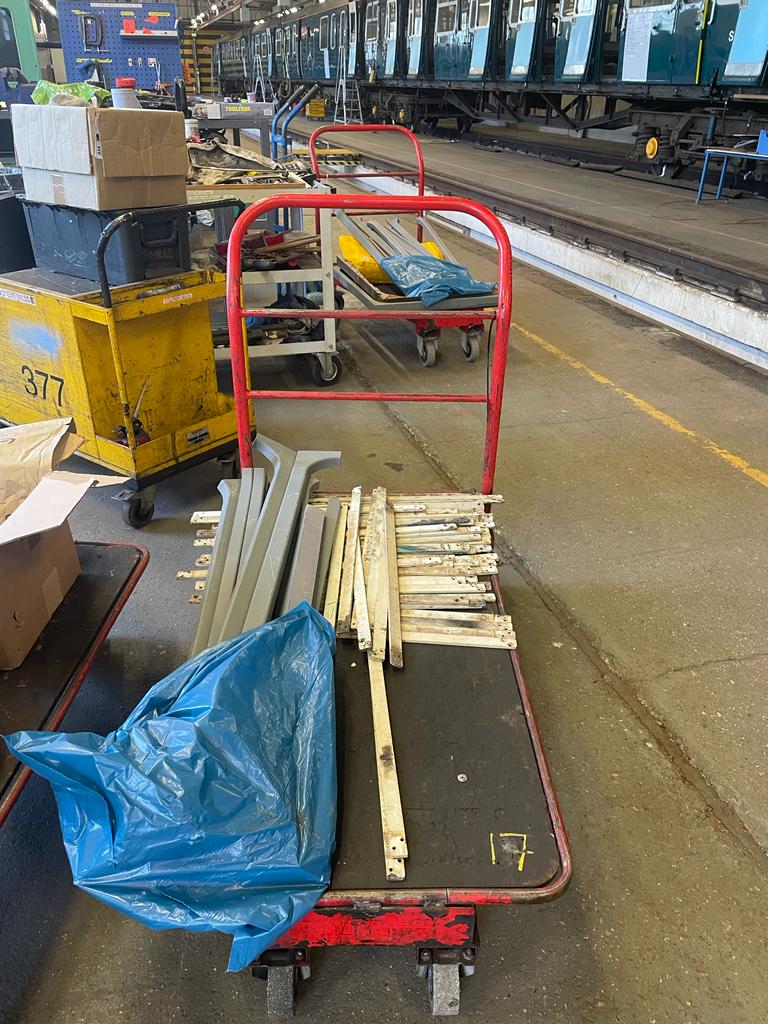

Inside the shed we have been just as busy. As part of the Digital Stores plan, we have begun labelling all the equipment in our stores. This is proving something of a challenge for those of us who don’t come from a maintenance background, because it’s been explained using Agricultural & Forthright Language (in other words we’ve been sworn at – loudly) that simply writing “Box with wires, covered in dust, grey with brown bits on it” isn’t an acceptable technical designation for a Loudaphone. While the stores were being labelled, we also identified a lack of available shelving space. To correct this, we have purchased a batch of new industrial racking and over the next few months we will be assembling these new shelves in the current stores area and moving equipment on to them. Again employing best practice learned from SWR and elsewhere in the industry – along with having a digital inventory of what’s what and where it is – we intend to be able to know at a moment’s notice what equipment we have and where. Sounds obvious, but it will be a world away from where we started. If we had a permanent stores staff, this would be less of a priority but with a small group it’s essential we have a reliable system that means no one has to remember where everything is!

Darren and Buckie have sourced and installed a new machine bench with a pillar drill and grinder attached. Behind this we are planning to have a large wood-working bench built, so that all out machining and woodwork tasks can happen ‘back to back’, with tools, templates and materials easily to hand. This marks a firm departure in the layout of the shed, moving away from a ‘parts built/repaired off-site, then delivered from & fitted on-site’ to (at least some) parts built and fitted on-site. As with the Trim Shop, we want to move towards a place where we can strip, rebuild or make from scratch at least some of the fittings we need for the unit. As well as this we have purchased a small scaffold tower to allow examinations of the roof of the unit; our depot instructions and staff competencies will cover when and who will use this equipment.

And then there’s the unit itself (did you think I’d forgotten?!)….

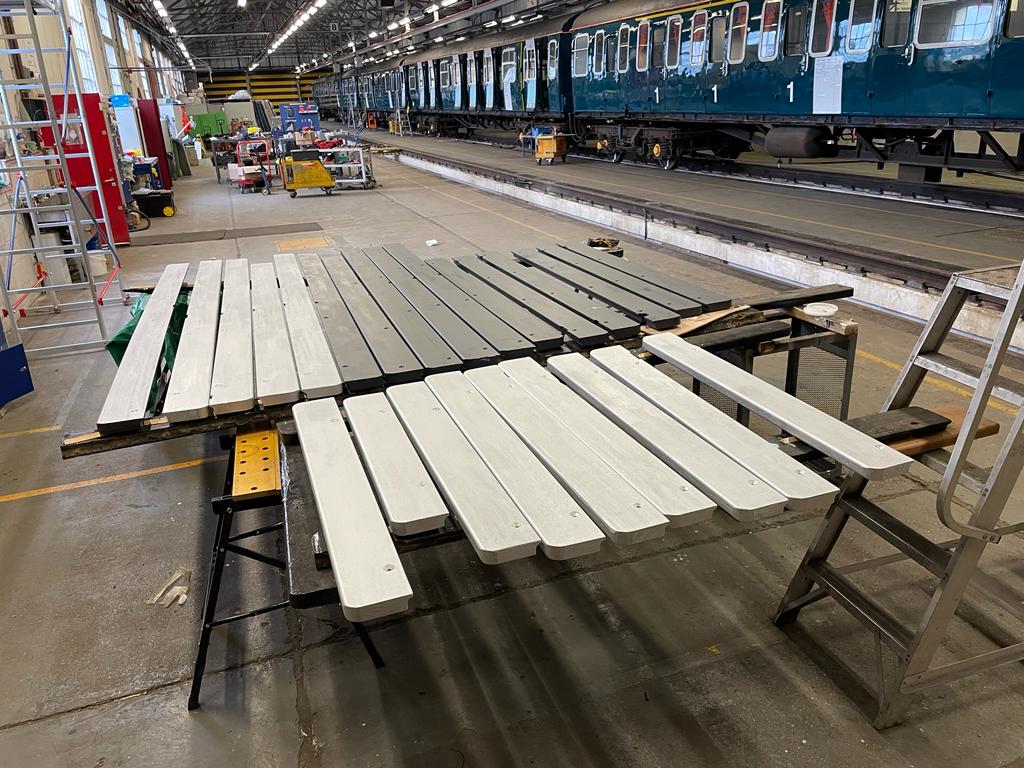

The interior of 76262 is now largely complete; first class quarter pads have been made up from the components of the water-damaged originals, two large sidelights (the big passenger saloon windows) require frame to frame drain pipes fitting, as do the first class compartment windows, standard quarter pads have been made up and are ready for fitting, we have the standard seat bases and backs ready to fit as well. So, as usual, we’re waiting for a few jobs to be done before we cab box-up a lot of smaller jobs. And was that’s done – bingo! We have our compartments and saloon ready for use. That will be a very very good day indeed. 76262’s driving cab is in the midst of an overhaul. All the required wooden components have been machined off-site by our resident woodworking genius Richard Salmon and we are now completing a few other tasks before throwing ourselves into the cab rebuild. This ties in neatly with our plans to create a woodworking station on-site, as well as the appeal of expanding our volunteer base to allow these jobs to be attacked simultaneously rather than one at a time. at present we have to very much prioritise once task before moving on to the next. Elsewhere we have fitted a batch of original ex-4VEp orange curtains to the first class compartments in place of the ex-SWT blue ones. The effect of the orange against he Spec-81 blue bodywork is quite striking, and enhances the look of the unit. Thanks are again due to the Bluebell Railway and their C&W department for finding these in their stores and kindly passing them on to us. Top job!

Buckie has, since he completed the overhaul of our paperwork and filing systems, been pleased to be back in the shed and getting his hands dirty again. He has begun researching what will be required to fit the unit with LED headlamps in place of the existing WIPAC filament fittings, as well as working to repair a long-standing fault with the pilot isolating valve on 76263. This valve lives on the very bottom of the driver’s power controller assembly and sends an air signal to the brake controller, which allows the train brake pipe to be charged when the driver opens up the driving controls with his EP Key. It has done us a great deal of good to hear the muffled swearing and cursing as he fights with this rather awkwardly placed bit of kit. And it’s also been a joy to hear him stomping across the shed floor, vowing vengeance on design engineers and threatening to fetch petrol and matches to “solve the bloody problem once and for all.” Don’t worry folks, he doesn’t mean it. But it is a bloody awkward job! Last of the present task for the ‘upstairs accommodation’ is designing and fitting Drop Light Blocks to restrict the travel fo the passenger drop light windows while the unit is in service. With the news of an operator having their operating licence suspended owing to safety-case infringements involved exactly these kinds of windows, we’re trying to get ‘ahead of the game’ when the time comes for the unit to once again run in service. Away from ‘Upstairs’, we have begun cleaning the underarms and bogies prior to a repaint, the unit has been moved back and forth using a pinch bar to protect the wheel bearings and we working towards a derogation from the standard Ultrasonic Axle Testing Regime, which at present is required every 6 months regardless of mileage. We are look towards making this mileage based.

Away from the shed and the unit, we have chipped in with the effort to preserve one of Southern’s Class 313 units. Thanks to Darren and his array of contacts at Southern we have managed to secure important spares and documentation that, we hope, will help this project to move forward. After all, we ‘re all on the same side. We wish them the best of luck (and speaking from bitter experience, they’re going to need it!!) And finally, we are delighted to welcome Kieran O’Shea, Dave Cooper and Phil Best to the SETG volunteer roster.

So there you have it – a good couple of months of work condensed down into a few paragraphs! On behalf of myself, Buckie, Daz, Lynn, Coops, JD, Mick, New Boy Dave, Kieran and everyone else who I’ve forgotten owing to old age, thank you to all our supporters who read our tweets, follow us on Facebook and read these web updates. Don’t forget that we are always looking for further expressions of support and you can give a one-off donation or make regular subscription payments to us via PayPal on our donations page*.

* – Please note that despite Buckie’s pleas, none of the money donated will be spent on a Jaguar XR-R in Blue Blue with Half Yellow ends: every penny goes to the restoration of 3417.